Angina Pectoris

No matter how healthy we think we are, there is always something lurking around the corner waiting to pounce. When I stop to think about what happened to me I realised that this wasn't me just getting older, this was a progressive thing that had been sneaking up on me for at least three years, possibly more and I just got used to it.

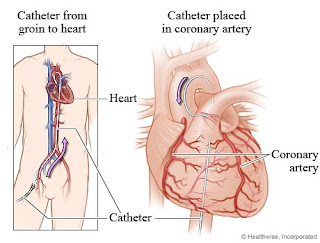

Angioplasty: The proceedure.

Angioplasty: The proceedure.A thin soft tube called a catherter is used for cardiac catherterization and angioplasty proceedures. The doctor inserts the catherter into a blood vessel in the groin as per the image, wrist, or above the elbow. The doctor carefully guides the catherter through the blood vessels into the corany arteries of the heart all the while using an X-Ray screen to watch the movement of the catherter in the blood vessels. The catherter in my case carried a collapsed stent which had a balloon inside of it. When in the correct position it was inflated to lock each of the stents in place. The ballon is then deflated and the catherter withdrawn from the blood vessel. Pressure is then applies to the blood vessel openning to seal it. After a period of time this is removed usually from four to six hours dependant on the entry point. The high light of the recovery process is the need to consume a minimum of two litres of water to flush the radioisotopes from the kidneys all within two hours. Think about it, and what happens when the need to pass water while on the broad of your back. I have to admit it was the cause of a lot of humour in the recovery ward at the time and unable to hold your own.

August this year didn't bode well for your's truly. You have a birthday with a difference, one I don't want a repeat of, caught on a wet miserable afternoon rushing to get to the car at the other end of town in pouring rain, sudden chest pain and shortness of breath. Traffic lights RED! Soaked to the skin and still at least 150metres to go across an intersection then helter-skelter for the car park. The pain still persisted and out of breath so another stop in the hope it would pass.

Eventually I reached the car and found that my mobile phone was at home and I needed help. All I could do was sit and wait in the hope that what ever the problem was would pass though temporarily so I could get home.

When I eventually arrived home, Joan took one look at me and asked the obvious question. "Are you alright?" after a few moments she was convinced I needed a Dr. and ASAP. Now have you ever tried to see a Doctor at a minutes notice? It just doesn't happen. First it was a 14 day wait, then it was the following Wednesday. Not good enough. The next morning our youngest daughter hit the phone and I had an appointment that afternoon, so the wheels started turning.

X-Rays, ECG's, EKG's, blood tests, Consultant Physician, stress test, and finally off to the Launceston General Hostiptal Cath-Lab for an Angiogram, then a second stress test, hence the cartoon making its appearance. (Thanks Davo.) It was one stress test I never want to be repeated as I thought I was a gonner. Three minutes thirty seconds after starting I was flat on the floor and requiring revival. Diagnosed with Angina Pectoris. A better result than a heart attack, the heart had suffered no damage so I was lucky. I must say that it was the most uncomfortable 125km trip home I have ever experienced.

Within days I was back for the Angioplasty ( insertion of stents ) for two 98% blocked arteries via incissions in the wrist, a departure from entry via the groin which I had been prepped for twice and wasn't required. (I think the nurses were just getting in some practice at my expense.) The recovery time being at least two hours less, and certainly much less trauma involved, and certainly bruising wasn't an issue.

At this point I want to make it clear to those who may have to follow me down this path. It is no big deal for either the angiogram, or the resulting angioplasty. You are fully conscious with only a local anaesthetic administerd, a small prick at any of the entry points. There is no sensation of the catherter passing through the blood vessels as there are no nerve recepters attached to them. What you may have afterwards is a sensation that there is something foreign in the chest cavity, you will soon ingore that as a part of life.

So here I was barely able to crawl into the Day Surgery admissions at 0830hrs, and by 1645hrs litterally ran out of the hospital like a startled gazelle.

When I think back on it, my father had the same problem in 1970. He was stuck with taking angernine tablets under his tongue plus assorted medication. This sort of cardiac intervention wasn't considered an option forty years ago. He managed to survive a further twelve years putting up with the discomfort if he over exerted himself and that was all too often.

So what is the message in all of this.

(1) If you find yourself in a similar situation, get an ambulance pronto. I was lucky, some one else may not be. Dial 000, (Australia wide) immediately, or your countries emergency number.

(2) Always involve your partner when visiting the doctor of consultants. Two pair of ears are better than one and means that if one missed a point the other picked it up.

(3) Accept good advice from your doctor, consultant physician, and cardiac specialists. It may not be what you want to hear, but you are a long time dead if you don't.

(4) Don't be afraid to share your experiences with others, you may just save their lives and above all be supportive, as you had been by others before your treatment.

I could mention so many names of the doctors, nurses, and people who offered valuable advice, and support, in the weeks and days prior to entry to hospital. To them goes my heart felt thanks.

God bless you all.